المنتجات الساخنة

Mineral and Technological Features of

网页2021年3月24日 Mineralogical studies have established that the main iron-bearing mineral is hematite, which contains 69.02 to 70.35% of iron

Contact

(PDF) Eco-Efficient and Cost-Effective Process

网页2013年9月16日 Design for Magnetite Iron Ore. Alex Jankovic, PhD. Queensland Centre for Advanced Technology . 1 Technology Court,

Contact

Developments in the physical separation of iron ore:

网页2015年1月1日 Development of large magnetic separator models can increase the ore treating capacity, reduce energy consumption, and save space. The largest permanent

Contact

Eco-efficient and cost-effective process design for magnetite iron ore

网页2015年2月24日 This fundamental property of a magnetite ore is generally one of the major drivers of flowsheet design and, therefore, flowsheet option generation. Four circuit

Contact

(PDF) Reducing Grinding Energy and Cost

网页2010年1月1日 A theoretical design study for a for high capacity processing of a hard, fine grained silica rich magnetite ore, with several circuit options was carried out to assess the energy efficiency

Contact

Optimization of Reduction Parameters of Quenched Titaniferous Magnetite

网页2019年4月25日 To improve the reducibility of titaniferous magnetite ore (TMO), a technique of high-temperature heating followed by water quenching has been adapted.

Contact

Hydrogen Reduction of Hematite Ore Fines to

网页Surplus coke oven gases (COGs) and low grade hematite ores are abundant in Shanxi, China. Our group proposes a new process that could simultaneously enrich CH 4 from COG and produce separated magnetite

Contact

Magnetite Magnetic Properties, Iron Oxide,

网页2023年6月2日 magnetite, also called lodestone, or magnetic iron ore, iron oxide mineral (FeFe 2 O 4, or Fe 3 O 4) that is the chief member of one of the series of the spinel (q.v.) group.Minerals in this series form black to

Contact

Magnetite an overview ScienceDirect Topics

网页Magnetite nanoparticles were synthesized with Fusarium oxysporum, ferric chloride and magnetite ore as substrates. SEM indicated that both types of nanoparticles were

Contact

Eco-efficient and cost-effective process design for magnetite iron ore

网页2015年2月24日 This fundamental property of a magnetite ore is generally one of the major drivers of flowsheet design and, therefore, flowsheet option generation. Four circuit options were selected for comparison (McNab et al, 2009) with the following acronyms used to identify the primary unit process within each:

Contact

Magnetic separation studies for a low grade siliceous iron ore sample

网页2013年1月1日 The investigations carried out on the low grade iron ore sample reveal the following conclusions. (1) The sample on average contains 43.8% Fe, 16.8% SiO 2 and 5.61% Al 2 O 3. (2) The mineralogical studies indicate that the major iron minerals are magnetite, hematite and goethite. And the gangue minerals are silicates and calcites.

Contact

A Novel Pneumatic Planar Magnetic Separator for

网页2020年8月27日 In our previous studies, we investigated the performance of a novel pneumatic planar magnetic separator (PMS) for the dry beneficiation of a selected magnetite ore. In the present study, we have

Contact

Optimization of Reduction Parameters of Quenched Titaniferous Magnetite

网页2019年4月25日 To improve the reducibility of titaniferous magnetite ore (TMO), a technique of high-temperature heating followed by water quenching has been adapted. Application of the Box–Behnken Design. The titaniferous magnetite ore (TMO) having particle size (− 18.75 mm + 12.5 mm) and lean grade coal fines (below 75 µm particle size) have been

Contact

(PDF) Economic Geology Mineral Resources

网页2017年10月10日 Magnetite Fe 3O4. Metal li c Element s Ore Min era ls Chemical Form ulae Industr ial Usage. Chalcopyrit e CuFeS2. Bornit e Cu5FeS2. Native gold Au. Electr um Au Ag. Lead (Pb) Gale na PbS

Contact

Recovery of Vanadium from Magnetite Ore Using Direct Acid

网页2018年3月23日 Recovery of vanadium from magnetite ore by direct acid leaching is discussed. The proposed process, which employs a mixture of nitric and sulfuric acids, avoids pyrometallurgical treatments since such treatment consumes a high amount of energy. To determine the optimum conditions of vanadium recovery, the leaching

Contact

What size mill do I need GrindingClassification Circuits

网页2023年7月19日 How do I size and design a mill for magnetite ore types with 75-250 t/h working? The ore consists of about 30% quartz and 30% magnetite and the amount of hematite is lesser than magnetite. By the way, Citic Pacific's Sino Iron Project will be processing magnetite ore using 6 AG mills, 17 meters high and consuming 44 MW each.

Contact

Mineral and Technological Features of

网页2021年3月24日 Mineralogical studies have established that the main iron-bearing mineral is hematite, which contains 69.02 to 70.35% of iron distributed in the ore. Magnetite and hydrogoethite account for

Contact

Assessing the performance of a novel pneumatic magnetic separator for

网页2020年9月1日 The design and operation of the PMS eliminate dust pollution. Some optimisation and comparative studies conducted using the PMS on different magnetite ores have been presented by Baawuah et a magnetite ore sourced from South Australia was used to investigate the effect of feed particle sizes on the performance of the PMS and

Contact

Optimization of Quenching Parameters for the Reduction of

网页2018年6月4日 In the present study, a unique method is adopted to achieve higher reducibility of titaniferous magnetite lump ore (TMO). In this method, TMO is initially heated followed by water quenching. The quenching process generates cracks due to thermal shock in the dense TMO lumps, which, in turn, increases the extent of reduction (EOR) using

Contact

Recovery of iron as a form of ferrous acetate precipitates from low

网页2010年11月1日 This stone describes the recovery process of iron as a form of ferrous acetate from low-grade magnetite ore (Shinyemi Mine, Gangwon province, Korea). The magnetically separated magnetite powder was dissolved in aqueous oxalic acid solution. The dissolution fraction of magnetite concentrates was measured as a function of initial

Contact

Optimising Western Australia Magnetite Circuit Design

网页2 天之前 Optimising Western Australia Magnetite Circuit Design D David1, M Larson2 and M Li3 1. FAusIMM, Process Consultant, AMEC Minproc, Level 14, 140 St Georges Terrace, Perth WA 6000. Email: dean.david@amec All of the ore was ground in the AMMTEC pilot AG mill (1.74 m diameter inside liners and 0.46 m EGL) and then run through the

Contact

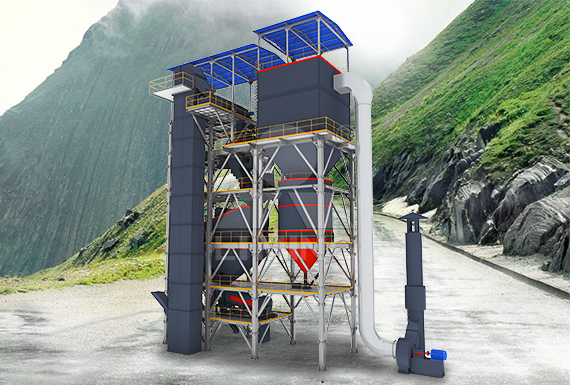

Minerals Free Full-Text Study on Magnetite Ore Crushing

网页2021年9月10日 High energy consumption in ore crushing brings great challenges to the mining industry. Microwave irradiation provides a promising solution for rock breaking. However, there is currently a lack of detailed understanding of the microwave parameters regarding magnetite ore. The purpose of this study is to fully understand the potential

Contact

Magnetizing Reduction and Magnetic Separation Studies

网页2021年6月11日 The ore to coal ratio was studied from 1: 0.1 to 1: 0.30, the reduction temperature was ranged from 500 to 800 °C, the residence time was varied between 30 min to 120 min and the particle size of ore was varied from 90-95% passing 100 mesh to 250 mesh. Magnetic Separation Tests The reduced ore (feed) was subjected to wet low intensity

Contact

Magnetite Concentration Methods 911

网页2018年2月6日 Magnetite (composition Fe3O4) has a specific gravity ranging from 5.0 to 5.1, and is sufficiently heavy to permit of its concentration from gangue by specific-gravity methods, which have had

Contact

Hydrogen Reduction of Hematite Ore Fines to

网页Surplus coke oven gases (COGs) and low grade hematite ores are abundant in Shanxi, China. Our group proposes a new process that could simultaneously enrich CH 4 from COG and produce separated magnetite

Contact

Magnetic Separator an overview ScienceDirect Topics

网页Developments in the physical separation of iron ore. D. Xiong, R.J. Holmes, in Iron Ore, 2015 9.5.2 Utilization of subeconomic iron ores. As magnetic separators progress toward larger capacity, higher efficiency, and lower operating costs, some subeconomic iron ores have been utilized in recent years. For example, magnetite iron ore containing only about

Contact

Magnetite an overview ScienceDirect Topics

网页Magnetite nanoparticles were synthesized with Fusarium oxysporum, ferric chloride and magnetite ore as substrates. SEM indicated that both types of nanoparticles were spherical, globular, and irregular in shape with a narrow size distribution in the range 27.54–81.22 nm. In Mineral Processing Design and Operations (Second Edition), 2016

Contact

(PDF) Possibilities of two-stage processing of

网页2011年6月1日 The technique and results of laboratory studies of the two-stage processing of the iron-vanadium and ilmenite concentrates produced from the titaniferous magnetite ores of Southern Ural deposits

Contact

Developments in the physical separation of iron ore:

网页2015年1月1日 Development of large magnetic separator models can increase the ore treating capacity, reduce energy consumption, and save space. The largest permanent magnetic drum separator is 1800 mm in diameter and 5000 mm in length, and the capacity for treating magnetite ore is 250–300 ton of feed per hour.

Contact