المنتجات الساخنة

Effects of ultrafine grinding time on the functional and flavor

网页2020年12月1日 With prolonging the ultrafine grinding processing time, the solubility, foaming and emulsifying properties of SPI powders were improved, the content ofα-helix,

Contact

Superfine and Ultrafine Grinding— A Literature Survey

网页2022年8月11日 Stirred ball mills are used in ultrafine grinding because of their high unit outputs, while the low amplitude vibro-energy mills are used because of their low specific

Contact

Ultrafine grinding of wheat : Effect of /starch

网页2020年5月1日 Furthermore, the ultrafine grinding technique can affect the thermal characteristics of /starch, as the starch granular structure changes. In agreement

Contact

Effect of ultrafine grinding technology combined with high

网页2022年1月15日 Effect of ultrafine grinding technology combined with high-pressure, microwave and high-temperature cooking technology on the physicochemical properties

Contact

Effects of different physical technology on compositions and

网页2021年10月1日 Ultrafine grinding is often used to change the structure and specific surface area of raw materials. It is mainly used for the modification of grain, such as whole wheat

Contact

Effects of ultrafine grinding time on the functional and flavor

网页2020年12月1日 As shown in Fig. 1 A, the peak 1of SPI powders at grinding time 2, 4, 6 and 8 h had a single and narrow distribution compared to that of grinding time 0 h. Moreover,

Contact

Ultrafine Grinding a Promising Method for Improving the

网页2019年2月19日 This study aims at determining the microstructure, particle size, composition ratio and physicochemical properties of ultrafine pulverized potato peel

Contact

Effects of ultrafine grinding on physicochemical, functional and

网页With a reduced particle size, the solubility of ultrafine powders increased significantly (P < 0.05), whereas the water holding and swelling capacities decreased with a reduced

Contact

Effects of ultrafine grinding on physicochemical, functional

网页Fourier transform infrared spectroscopy analysis showed that ultrafine grinding did not damage the main cellular structure of GS powder. The reduction of fiber length and

Contact

Changes to the physicochemical characteristics of wheat

网页2014年8月6日 To investigate changes on the physicochemical characteristics of wheat straw by mechanical ultrafine grinding, wheat straw powders of four different particle sizes and distributions were produced using a sieve-based Retsch ZM100 grind mill and CJM-SY-B ultrafine vibration grind mill. Changes on the microstructure and physicochemical

Contact

Effect of ultrafine grinding technology combined with high

网页2022年1月15日 Effect of ultrafine grinding technology combined with high-pressure, microwave and high-temperature cooking technology on the physicochemical properties of bean dregs 2014; JingChi, 2013; Li, Qiao,Lu, 2012). Steam explosion (SE) could increase the content of SDF of bean dregs from 1.34% to 36.28% under explosion

Contact

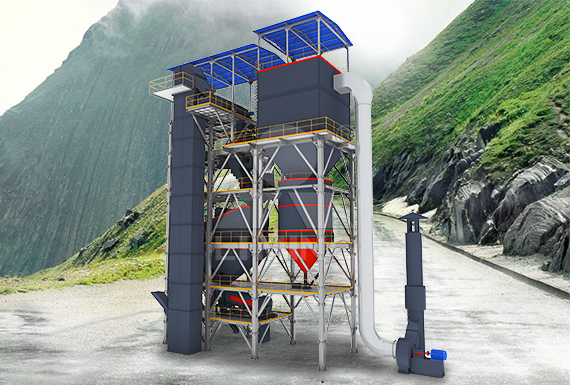

Ultra Fine Grinding Mill mpl Ultrafine Powder

网页Ultra Fine Grinding Mill. Discharge fineness: 150~3000 meshes. Feed size.: <25 mm. Output: 0.5-45 t/h. Product features: High safety and reliability. Easy to operate Energy efficient Environmental protection and pollution

Contact

The onset of particle agglomeration during the dry ultrafine grinding

网页2015年11月1日 The ultrafine grinding occurs in different types of high energy mills, which the most common are vibratory, planetary, air-jet and stirred media mills [1], [2]. In mineral processing, the main application of high-energy milling is size reduction of industrial minerals such as quartz and quartzite, feldspars, carbonate rocks, kaolinite and

Contact

Ultrafine Friction Grinding of Lignin for

网页2021年6月21日 The work demonstrates the utilization of fractionalized lignin from the black liquor of soda pulping for the development of starch-lignin biocomposites. The effect of ultrafine friction grinding on lignin

Contact

Effects of UV-C treatment and ultrafine-grinding on the

网页2020年3月30日 In the present study, the impact of ultraviolet (UV)-C treatment and ultrafine grinding on the conversion of ergosterol to vitamin D 2, physiochemical properties, and antioxidant properties of shiitake and Jew’s ear was assessed.After exposure to UV-C, vitamin D 2 contents of both the mushroom samples has increased significantly (p <

Contact

Effects of Airflow Ultrafine-Grinding on the

网页2021年9月26日 Five different ultrafine milled s (UMFs) were prepared from Tartary buckwheat via airflow ultrafine-grinding at different grinding pressures. The airflow ultrafine-grinding resulted in marked differences in

Contact

Ultrafine Grinding a Promising Method for Improving the

网页2019年2月19日 This study aims at determining the microstructure, particle size, composition ratio and physicochemical properties of ultrafine pulverized potato peel waste (PPW) obtained from expanded and unexpanded extrusion methods. Results obtained in our study show that ultrafine grinding processes significantly modify the structural properties

Contact

Ultrafine grinding of wheat : Effect of

网页Furthermore, the ultrafine grinding technique can affect the thermal characteristics of /starch, as the starch granular structure changes. In agreement with our results, a previous study reported that the RVA FV of

Contact

Effects of Ultrafine Grinding and Pulsed Magnetic Field

网页2017年8月27日 effects of ultrafine grinding and pulsed magnetic field (PMF) treatment on free gossypol (FG) content in cottonseed meal (CSM). The results revealed that FG content decreased from 831 to 584 mg kg−1 after CSM was ultrafine ground with an airflow crusher. A further decrease of FG content was achieved byprocessingwith PMF.

Contact

Ultrafine grinding of wheat : Effect of /starch

网页2020年5月1日 Furthermore, the ultrafine grinding technique can affect the thermal characteristics of /starch, as the starch granular structure changes. In agreement with our results, a previous study reported that the RVA FV of was strongly correlated with the degree of damage present in starch granules (Hasjim, Li,Dhital, 2013).

Contact

Effects of ultrafine grinding time on the functional and flavor

网页2020年12月1日 With prolonging the ultrafine grinding processing time, the solubility, foaming and emulsifying properties of SPI powders were improved, the content ofα-helix, β-sheet and random coils increased, while β-turn decreased. Furthermore, the ultrafine grinding time clearly influenced the volatile compounds of SPI powders. (2013) View

Contact

Effect of vibrating-type ultrafine grinding on the

网页2018年11月1日 We evaluated the influence of a vibrating-type ultrafine grinding treatment on the physical and chemical properties and antioxidant activity of Turkish gall powder (TGP) with particle sizes of >450, 400–250, 250–100, 100–50, and < 50 μm. The physical properties were analyzed and we found that the small particle size of the TGP increased

Contact

Physicochemical and antioxidant properties of dietary fibers

网页2014年10月1日 The particle size of Qingke DF after ultrafine grinding was distributed in a range from 2.97 μm to 39.23 μm with a mean particle size of 11.74 μm, which belongs to the submicron scale (Fig. 2).Instead, the mean particle size of Qingke DF before ultrafine grinding was 172.49 μm.The results showed that pulverization by the mini-type airflow

Contact

(PDF) FINE GRINDING IN THE AUSTRALIAN

网页2003年1月1日 The present literature review explores the energy-efficient ultrafine grinding of particles using stirred mills. The review provides an overview of the different techniques for size reduction and

Contact

Alterations in physicochemical properties and bile acid

网页2018年2月15日 The WRC, SP, WSI, syneresis, and turbidity of each DF sample were measured before and after ultrafine grinding and are summarized in Table 3.According to Table 3, guar gum had the highest WRC in 60.81 g/g before ultrafine grinding, followed by a decline in WRC after ultrafine grinding. However, the WRC of other three DF samples

Contact

Modifying crystallinity, and thermo-optical characteristics of

网页2020年10月1日 The ultrafine grinding pretreatment not only destroy the crystallinity, but also remarkably alters the surface structure of the particulate, particle size and hence surface area which can remarkably influence the performance of enzymes to increase the digestibility and hence increase the biohydrogen production. Technol., 116 (2013), pp.

Contact

Ultrafine Grinding in Contemporary Flow Diagrams for

网页2015年7月21日 Bead mills are characterized by high throughput and a high energy-conversion factor when they are used for fine and ultrafine grinding. A comparative analysis of bead mills and conventional ball mills (Table 1) showed that the use of bead mills for the comminution of material to fractions on the order of 10 μm makes it possible to reduce

Contact

Application of superfine pulverization technology in Biomaterial

网页2009年5月1日 Superfine grinding methods including airflow grinding, liquid flow grinding, low-temperature grinding, ball milling, ultrasonic disintegrator grinding, etc. [21]. To date, this ultrafine grinding

Contact

A novel film–pore–surface diffusion model to explain the

网页2016年8月30日 Ultrafine grinding is an environmentally friendly pretreatment that can alter the degree of polymerization, the porosity and the specific surface area of lignocellulosic biomass and can, thus, enhance cellulose hydrolysis. Enzyme adsorption onto the substrate is a prerequisite for the enzymatic hydrolysis process. Therefore, it is necessary to

Contact