المنتجات الساخنة

Effects of calcination on silica phase transition in diatomite

网页2018年8月15日 2.2. High-temperature experiments. For experiments in high-temperature treatment of diatomite, 25 g of diatomite dried in oven at 105 °C for 4 h as raw material was taken into a crucible and then calcined in a muffle furnace (SX2-8-13, Jianli, Yingshan, China) at the temperature range from 200 °C to 1200 °C for the holding time 1.5 h.

Contact

The preparation and characterization of calcined diatomite with

网页2022年3月5日 The flux calcined diatomite (C-D) which produced by Na 2 CO 3 calcination was obtained from Linjiang, China. Lime (CaO) is analytical reagent (from Shanghai Zhenxin Reagent Co., Shanghai, China) and aqueous solutions were prepared by using distilled water. The adsorption experiments were carried out in methylene blue solution, and the

Contact

Mechanical and microstructural properties of calcined diatomite

网页2020年7月1日 In another work, diatomite calcined to improve its pozzolanic activity and employed as cement substitute material. Then, the extracted diatomite rocks were crushed stone crushing machine and grounded in the grinder mill. The crushed and grounded diatomite rocks were calcined for two hour at 650 °C, 750 °C, 850 °C, 950 °C

Contact

The use of raw and calcined diatomite in cement production

网页2008年3月1日 The grindability of raw and calcined diatomite are different. Under normal conditions, raw diatomite are grinded more easily, however, calcined diatomite eased the grinding when milled together with clinker. This fact can provide considerable energy saving in the milling operations of cement production. –

Contact

AP-42, CH 11.22: Diatomite Processing US EPA

网页2015年9月10日 11/95 Diatomite Processing 11.22-1 11.22 Diatomite Processing 11.22.1 Process Description1-2 Diatomite is a chalky, sedimentary rock consisting mainly of an accumulation of skeletons For filtration uses, natural grade diatomite is calcined by heat treatment in gas- or fuel oil-fired rotary calciners, with or without a fluxing agent. Typical

Contact

Figure 1. Typical process flow diagram for diatomite

网页2021年6月25日 For filtration uses, natural grade diatomite is calcined by heat treatment in gas- or fuel oil-fired rotary calciners, with or without a fluxing agent. Typical calciner operating temperatures range from 650° to 1200°C (1200° to 2200°F). For straight-calcined grades, the powder is heated to the point of

Contact

Mechanochemical preparation of calcined diatomite/α

网页Calcined diatomite/α-Fe 2 O 3 composite particle materials (CD/α-F) were prepared with calcined diatomite and α-Fe 2 O 3 as raw materials by a mechanochemical method in the system of wet grinding. Scanning electron microscopy, energy dispersive spectrometry, hiding power and oil absorption measurements were used to characterize the

Contact

XRD patterns of the calcined diatomite (a) 900°C (b) 1,000°C

网页The X-ray diffraction analyses of these calcined diatomite samples are shown in Figure 5. The XRD patterns of the calcined diatomite at 900°C show an additional peak at 19.8° 2θ, beside the

Contact

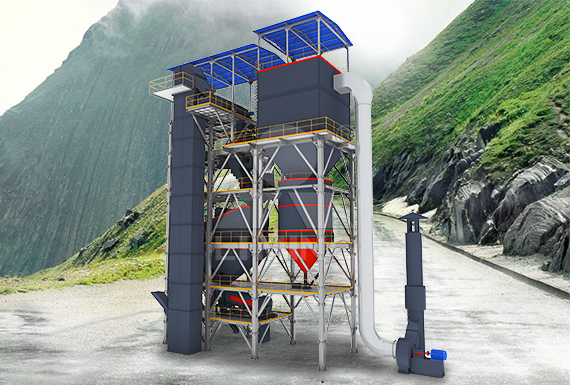

Diatomite Ultrafine Grinding Mill mpl Ultrafine

网页2021年9月9日 14 45-5μm HGM Series Ultrafine Mill. Diatomite ultrafine grinding mill is a highly efficient ores powder grinder machine. It can grind diatomite into a fine powder (150-3000 mesh), and the fineness can be

Contact

Diatomite Grinding Machine and Processing Line

网页2023年1月19日 Diatomite Grinding Machine. As for diatomite grinding mill, customers can choose the different kinds according to different production requirements, such as vertical mill, ball mill, trapezium mill, and so on. All of them our company and provide. And all of them are designed by our experienced engineers based on many years’ research.

Contact

The Resistance of Composite Cement Paste with Calcined Diatomite

网页2023年3月11日 The CDP was made by grinding diatomite chunk collected from Beureunuet Village, Aceh Besar District, Indonesia, and sieving under #200 mesh. The diatomite powder was then dried in the oven at the temperature of 100 °C for 24 h and calcined in the laboratory furnace at the temperature of 650 °C for 5 h.

Contact

Figure 1. Typical process flow diagram for diatomite

网页2021年6月25日 For filtration uses, natural grade diatomite is calcined by heat treatment in gas- or fuel oil-fired rotary calciners, with or without a fluxing agent. Typical calciner operating temperatures range from 650° to 1200°C (1200° to 2200°F). For straight-calcined grades, the powder is heated to the point of

Contact

Diatomaceous Earth: Calcined vs. Non-Calcined Planet

网页2019年1月17日 Diatomaceous earth can be calcined or non-calcined. The difference between the two is very important depending on what purpose the DE is being used for. Calcined diatomaceous earth has been treated at a temperature above 1000 ºC. The purpose of this is to further harden the exoskeletons of the diatoms in order to create a

Contact

Crystals Free Full-Text A Novel Flux That

网页2022年4月4日 In raw and calcined diatomite samples, geochemical and mineralogical composition and parameters such as colour, grain size, morphology, specific surface area, permeability and wet cake density

Contact

The global variability of diatomaceous earth toxicity: a

网页2015年7月10日 During this process, the diatomite deposit (unprocessed DE) is treated at ~1000 °C with (flux-calcined) or without (calcined) the presence of a fluxing agent, usually sodium carbonate [1, 3]. During calcination, the amorphous silica is converted to crystalline silica, predominantly in the form of cristobalite [ 2,3 ].

Contact

Effect of elevated temperatures on properties of high

网页2022年9月15日 The best strength activity index is attained from mortars manufactured with GCD calcined at 850 °C as per ASTM C 311/C311M − 18 [45]. GCD has a specific gravity of 2.86 and BET fineness of 12.245 m 2 /g. The ground diatomite (GD) and GCD obtained from diatomite stones are shown in Fig. 1 b. The properties of PC and GCD are seen in Table 1.

Contact

A Guide to Safe Handling of Diatomaceous Earth Products

网页2019年11月20日 Diatomite ore is mined and then processed to produce a nal product which falls into one of three categories: a natural grade, a calcined grade, or a ux-calcined grade. The processing includes milling, drying, calcination, classi cation to produce a variety of particle-sized products from powders a few microns in

Contact

NATURAL AND CALCINED CLAYEY DIATOMITE AS

网页2019年4月21日 Diatomite was used in mortars at 5 to 15 wt. % substitution for cement, sand and water quantities were kept constant. The compressive and flexural strength decreased with increasing diatomite content. Calcined diatomite substitution generally increased the compressive strength of the cement mortar after 25 freezing and thawing

Contact

Diatomite: A promising natural candidate as carrier material

网页2015年7月1日 Fig. 1 schematically illustrates the procedure for “phase change diatomite”. The process is straightforward. PEG/diatomite fs-PCM was prepared using a vacuum impregnation method as reported by [15], [30]. Fig. 1 (a) illustrates the procedure of impregnation treatment with vacuuming. In order to observe the PEG leakage from the

Contact

en/diatomite calcining plant for sale.md at main

网页Contribute to jidafang2022/en development by creating an account on GitHub.

Contact

Diatomite Ultrafine Grinding Mill mpl Ultrafine

网页2021年9月9日 14 45-5μm HGM Series Ultrafine Mill. Diatomite ultrafine grinding mill is a highly efficient ores powder grinder machine. It can grind diatomite into a fine powder (150-3000 mesh), and the fineness can be

Contact

Crystals Free Full-Text A Novel Flux That Determines the

网页2022年4月4日 In raw and calcined diatomite samples, geochemical and mineralogical composition and parameters such as colour, grain size, morphology, specific surface area, permeability and wet cake density were characterized. SEM analysis of the samples showed that the diatom frustule structures were broken down as a result of grinding, but

Contact

Mechanical and microstructural properties of calcined diatomite

网页2020年6月1日 Sardemir et al. [20] found that the incorporation of diatomite by mixing calcined diatomite into cement mortar could effectively improve the strength of mortar, and 15% was the optimal dosage

Contact

Use of diatomite as partial replacement for Portland cement

网页2009年1月1日 A calcined diatomite sample with an amorphous silica content over 90% was added to the RAC mixture as a partial replacement of the ordinary Portland cement (OPC) at varying rates from 0 to 20 wt%. 75:25, and 100:0, were co-ground for the activation. It was performed by high-energy dry grinding to obtain completely (100%) and incompletely

Contact

Crystals Free Full-Text A Novel Flux That Determines the

网页2022年4月4日 In raw and calcined diatomite samples, geochemical and mineralogical composition and parameters such as colour, grain size, morphology, specific surface area, permeability and wet cake density were characterized. SEM analysis of the samples showed that the diatom frustule structures were broken down as a result of grinding, but

Contact

A study of diatomite and calcined kaoline properties in anticorrosion

网页2010年7月1日 The diatomaceous filler is an amorphous form of SiO 2 cristobalite, containing sodium, aluminium and iron admixtures. The filler was prepared by calcination above 1200 °C of a raw material containing shells of minute sea animals, followed by grinding.The filler based on calcined kaoline contains amorphous metakaoline.

Contact

sbm/sbm ball mill diatomite.md at main changjiangsx/sbm

网页Contribute to changjiangsx/sbm development by creating an account on GitHub.

Contact

The use of raw and calcined diatomite in cement production

网页2008年3月1日 Abstract. In this research, the use of raw and calcined diatomite which is in amorphous and porous nature was investigated in cement production. The physical, chemical, mineralogical, micro-structural and mechanical tests of the mortars, prepared by mixing Portland cement clinkers with 5%, 10% and 20% raw and calcined diatomite (w/w)

Contact

Mechanical and microstructural properties of calcined diatomite

网页2020年7月1日 In another work, diatomite calcined to improve its pozzolanic activity and employed as cement substitute material. Then, the extracted diatomite rocks were crushed stone crushing machine and grounded in the grinder mill. The crushed and grounded diatomite rocks were calcined for two hour at 650 °C, 750 °C, 850 °C, 950 °C

Contact

Effects of calcination on silica phase transition in diatomite

网页2018年8月15日 2.2. High-temperature experiments. For experiments in high-temperature treatment of diatomite, 25 g of diatomite dried in oven at 105 °C for 4 h as raw material was taken into a crucible and then calcined in a muffle furnace (SX2-8-13, Jianli, Yingshan, China) at the temperature range from 200 °C to 1200 °C for the holding time 1.5 h.

Contact