المنتجات الساخنة

How does a vertical raw mill work? LinkedIn

网页2022年12月26日A vertical raw mill works by grinding raw material such as cement, clay, limestone, phosphate, and sand into a fine powder. This powder is then passed through

Contact

Vertical roller mill for raw Application p rocess materials

网页In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to

Contact

Review on vertical roller mill in cement industryits

网页2021年1月1日The raw mill is either a Ball mill with two chambers or Vertical roller mill with inbuilt classifier. The hot gases from the pre heater enter the mill and are used for

Contact

Vertical Roller Mills

网页We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding

Contact

Prediction of raw meal fineness in the grinding process of

网页2020年10月24日The accurate prediction of raw meal fineness in the vertical mill system is very helpful for the operator to control the vertical mill. However, due to the

Contact

Vertical raw mill pradeep kumar SlideShare

网页2013年5月14日The principle of vertical mill resembles like ammi kallu, attaankallu, Or ennai chekku vandi. History of grinding technology. •Grinding •Separation •Drying •Conveying Four functions in one machine makes

Contact

Vertical Raw Mill Cement Raw Mill Raw Mill In Cement Plant

网页Vertical raw mill process Grinding : The raw material enters into the grinding through the sliding tube. Under the action of centrifugal force, it moves circumferential around

Contact

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant

网页In the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other

Contact

Vertical Raw Mill for Cement Raw Meal Grinding in

网页When the vertical raw material mill in the cement plant starts to run, the material enters the mill through the feed The transmission drives the millstone to rotate, and the grinding roller self-transmits around the

Contact

Vertical raw mill pradeep kumar SlideShare

网页2013年5月14日Vertical raw mill pradeep kumar. Vertical raw mill K.P.PRADEEP KUMAR Sr G M Operation Karikkali Works Chettinad Cements Ltd ; The principle of vertical mill resembles like ammi kallu,

Contact

Vertical Roller Mill Operation in Cement Plant

网页The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process.In recent years, the VRM cement mill has been equipped in more and

Contact

Cement Raw Mill in Cement Plant for Cement Raw

网页Raw mill is mainly used for grinding cement raw meal in the cement factory production process. It is also suitable for metallurgical, chemical, electric power and other industrial mining enterprises to grind various ores and

Contact

Raw Mill Feeding Cement Plant Optimization

网页Raw Mill Feeding. In the value stream map of cement manufacturing the raw mill feeding is an intermediate activity between Pre-homogenization and raw milling, and has not been discussed separately by most of the authors. However, in my opinion it remains and must remain as of pivotal importance, so far as the quality assurance is considered.

Contact

Industrial : Optimization for the Cement Industry ABB

网页Raw mix 10 sec 1 min Gas Material Coal feed Coal feed O 2 CO NO X Exit gas 340 °C Precalciner Air duct Kiln d=5m Grate cooler Clinker 60t Clinker (CaO compounds) 40t Co 2 + Dust 10kg (after E.P.) 100t Raw mix (CaCO 3) Measure and monitor process conditions Detect process condition changes Stabilise process with small frequent set-point

Contact

Optimizing Raw Mills Performance ; the Materials

网页2019年6月22日Limestone 11.30,Shale 16.40 ,Bauxite 9.45,Gypsum 8.16, Silica Sand 16.46,Iron Ore 15.44,Sand stone 11.53Dolomite 11.31. * It may please be noted that the HGIBond Work Index for a

Contact

WO2021093256A1 Raw material vertical mill external

网页A raw material vertical mill external circulation system, comprising a proportioning belt conveyor (29), a feed elevator (30), a feed conveying mechanism (31), a feed tee coupling (32), a V-shaped powder concentrator (33), an external circulation vertical roller mill (37), a cyclone (38), a circulation draught fan (39), and a bag type dust remover (40).

Contact

(PDF) ANALISIS EFISIENSI PERALATAN DAN HEAT LOSS

网页2022年7月11日Raw materials grinding process is a first step of cement production which is has an important role in the first grinding step. Vertical Raw Mill is a main equipment that is used in grinding or

Contact

Optimization of Vertical Raw Mill Operation PDF Scribd

网页Optimization of VRM Operation. Do not believe screen values unless you have checked them. Continuously change Process Parameters and document results to. find Optimum. Optimum is highest capacity at lowest power consumption. Be sensitive to changes of feed material and adapt parameters. Focus on Relevant Process Parameters only.

Contact

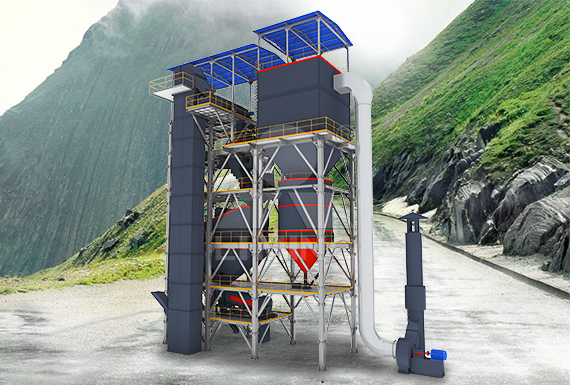

Vertical Raw Mill CHAENG

网页Vertical raw material mill is an important equipment widely used in the grinding section of cement raw meal (cement raw material) in the cement production process in cement plant. CHAENG manufactures cement

Contact

Raw Material Drying-Grinding Cement Plant Optimization

网页Dry Grinding: Open circuit Ball mill, closed circuit Ball mill, vertical roller mill, Roll Press or Roll press in circuit with ball mill. However, it would be seen that the most significant process and types used for raw material grinding operations in modern cement industry are: Process: Dry Closed circuit dry-grinding. Type of mill: Ball and

Contact

A Review on Pyroprocessing Techniques for

网页2020年2月9日1.5.3. Vertical Roller Mill (VRM) Vertical roller mills (VRMs) with integrated classifiers have been used successfully for many years in cement plants to grind and dry raw materials simultaneously

Contact

Roller Mill Based on Experimental Method MDPI

网页2022年1月23日and vertical roller mill i.e., VRM [3–5]. Among these devices, VRM plays an important role in cement, accounting for more than 55% of China’s cement raw meal market [6], and its performance directly affects the cost of producing cement. VRM has the functions of grinding and powder selection, including a grinding unit and an air classifier

Contact

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL

网页of the raw material [1, 2]. For VRM the production capacity denotes both the capacity of grinding and drying of mill. The grindability affects the capacity of grinding, type of mill and roller pressure. The capacity of the mill is calculated Using G K * D 2.51 Where, G is capacity of the mill, K1 is roller mill coefficient and D is table

Contact

Reducing energy consumption of a raw mill in cement industry

网页2012年6月1日Furthermore, the power consumption of the raw mill grinding process was reduced by 6.7 percent by using exterior hot gas, as suggested in an energy and exergy analysis of the mill by Atmaca

Contact

Coal mill, gypsum mill, clay mill, etc. Pfeiffer MPS mills

网页MPS 100 GC vertical roller mill for the grinding, drying and calcining of gypsum, Trevo, Brasil. MPS 3350 B mill for limestone grinding, China Chongqing Foreign Trade Huaneng, China. MPS 5000 B mill for raw

Contact

Operational parameters affecting the vertical roller mill

网页2017年4月1日Abstract. Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding. The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of

Contact

Optimization of Vertical Raw Mill Operation PDF Scribd

网页Save Save Optimization of Vertical Raw Mill Operation For Later. 93% 93% found this document useful, Mark this document as useful. 8% Do not believe screen values unless you have checked them Continuously change Process Parameters and document results to find Optimum Optimum is highest capacity at lowest power consumption Be sensitive to

Contact

(PDF) ANALISIS PENGGILINGAN DAN PENCAMPURAN KARAKTERISTIK PEMBUATAN

网页2022年1月11日instrument pada vertical raw mill, serta bahan baku pada pembuatan semen. B. Pengamatan Langsung (Observasi) Pada saat observasi lapangan di bimbing langsung oleh Bapak Muhammad Davi

Contact

Comparison Of Vertical Roller Mill And Roller Press Mill

网页After the long-term operation, although unit raw material grinding power consumption of the cement roller press grinding system is still low, the indexes of the vertical roller mill grinding system are very close to it, among which the output power of the vertical mill and the roller press contribute the same value to the unit power consumption, about 7~8kWh/t.

Contact