المنتجات الساخنة

Cement grinding optimisation ScienceDirect

网页2004年11月1日 Grinding occurs at the beginning and the end of the cement making process. Approximately 1.5 tonnes of raw materials are required to produce 1 tonne of

Contact

From raw materials Extracting raw materials Raw

网页2022年2月12日 Raw material preparation II: Drying and raw grinding Burning The burning of the raw meal at approx. 1,450°C is carried out in Lepol or preheater kilns that work by

Contact

Analysis of material flow and consumption in cement production

网页2016年1月20日 In the surveyed cement plant, three balances are established between input and output material in the raw mill, clinker production, and cement grinding system.

Contact

(PDF) Analysis of material flow and consumption

网页2015年8月1日 The results show that approximately 2.48t, 4.69t, and 3.41t of materials are required to produce a ton of the product in raw material

Contact

Review on vertical roller mill in cement industryits

网页2021年1月1日 Hence Ball MillVRM are major technologies in cement grinding. Their technological comparison is done beneath [8]. 4. Comparison among grinding

Contact

Reducing energy consumption of a raw mill in cement industry

网页2012年6月1日 About 2% of the electricity produced in the whole world is used during the grinding process of raw materials [1]. While total electrical energy consumption for

Contact

Advanced grinding in the cement industry Request PDF

网页2003年1月1日 Comminution is a crucial part of cement manufacture, which includes crushing and grinding of raw materials and clinker grinding. Comminution, however, is

Contact

CARBON DIOXIDE EMISSIONS FROM THE GLOBAL CEMENT INDUSTRY

网页2019年4月30日 The crushed material is screened, and stones are removed. Following crushing, the raw materials are further processed. The grinding process differs with the

Contact

en/crushing and grinding of raw material in a cement industry

网页英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Contact

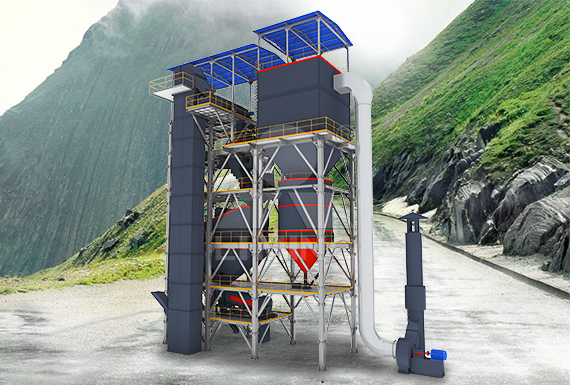

Raw Material Drying-Grinding Cement Plant Optimization

网页Grinding Operation Objectives and KPIs: Highly energy intensive unit operation of size reduction in cement industry is intended to provide a homogeneous, dry (<0.5% moisture) and super fine (10-20% residue on 90-micron sieve) raw meal powder for clinkerization process in kiln (Dry Process). Grinding operation is monitored for following

Contact

AIR POLUTION AND AIR POLLUTION CONTROL IN

网页2017年12月20日 Cement Industry. Cement manufacturing involves mining; crushing, and grinding of raw materials; calcination in a rotary/vertical kiln; cooling of the clinker; mixing with gypsum; and milling, storing, and bagging the finished cement. The process is very energy-intensive.

Contact

Review on vertical roller mill in cement industryits

网页2021年1月1日 Hence Ball MillVRM are major technologies in cement grinding. Their technological comparison is done beneath [8]. 4. Comparison among grinding technologies Ball mill V/s VRM. For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials.

Contact

(PDF) Cement Industry in Sri Lanka ResearchGate

网页2020年1月1日 Cement is used as a construction material in Sri Lanka. It is made with calcined lime and clay. Alumina, silica and iron oxide are the main substance of the clay. In Sri Lanka, the demand for

Contact

Cement industry news and events from World Cement with

网页2023年7月19日 CEMATRIX announces US$5.9 million in new contracts, backlog continues to grow to US$95.7 million. Wednesday 19 July 2023 16:37. CEMATRIX has executed US$5.9 million in new contracts to bring total contracts announced since the end of the fiscal year to US$21.7 million and US$58.3 million since August 3, 2022. Advertisement.

Contact

Integrated Pollution Prevention and Control (IPPC)

网页2020年3月4日 To produce 1 tonne of clinker the typical average consumption of raw materials in the EU is 1.57 tonnes. Most of the balance is lost from the process as carbon dioxide emission to air in the calcination reaction (CaCO3 → CaO + CO2). The cement industry is an energy intensive industry with energy typically accounting for 30-

Contact

Modeling of energy consumption factors for an industrial cement

网页2022年5月9日 Cement production is one of the most energy-intensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year's global electrical energy production. It is

Contact

Why is a crusher section used in the cement industry?

网页2023年3月1日 mpl mineral. A crusher section is used in the cement industry to reduce the size of raw materials such as limestone, clay, and other materials. The crushed material is then used as an input

Contact

Cement: Materials and manufacturing process Greenspec

网页Materials are extracted / quarried / recovered and transported to the cement plant. 2 Crushing and milling. The raw materials, limestone, shale, silica and iron oxice are crushed and milled into fine powders. 3 Mixing and preheating. The powders are blended (the ‘raw meal’) and preheated to around 900° C using the hot gases from the kiln.

Contact

Breakthrough in Clinker Grinding Massachusetts

网页2012年11月8日 The cement industry is particularly reliant upon particle size reduction. Raw materials crushing and grinding seeks to reduce materials from roughly one meter cubes of blasted stone to a size where at least 80 percent of the raw material is less than 75 microns. Finish grinding of clinker and other cement

Contact

Cement Kilns: Size Reduction and Grinding

网页2023年2月25日 The cement industry processes requiring fine grinding are rawmix preparation, fuel preparation and grinding of clinker to make cement. All three may require a preliminary crushing stage. In the case of raw

Contact

Crushing and Grinding Process JXSC Machine

网页2019年10月8日 The ore size reduction process involves two steps: crushing and grinding. The grinding process is the final operation of making the mineral to dissociate from the monomer and making the particle size

Contact

How does a raw mill work in a cement plant? LinkedIn

网页2022年12月19日 Grinding mills for cement plant. A raw mill is a key piece of equipment used in a cement plant to grind raw materials into a fine powder. It works by crushing and grinding materials such as

Contact

Environmental Pollution by Cement Industry

网页The raw materials are subjected to such processes as crushing, drying, grinding, proportioning, and blending before they are fed to the kilns for the burning process. The crushing stage involves

Contact

Cement grinding optimisation ScienceDirect

网页2004年11月1日 Grinding occurs at the beginning and the end of the cement making process. Approximately 1.5 tonnes of raw materials are required to produce 1 tonne of finished cement. The electrical energy consumed in the cement making process is in order of 110 kWh/tonne and about 30% of which is used for the raw materials preparation and

Contact

Cement Production an overview ScienceDirect Topics

网页Assessing the environmental impact of conventional and ‘green’ cement production. G. Habert, in Eco-efficient Construction and Building Materials, 2014 10.1 Introduction. Cement production has undergone tremendous developments since its beginnings some 2,000 years ago. While the use of cement in concrete has a very long history (Malinowsky, 1991), the

Contact

Grinding materials processing Britannica

网页In cement: Grinding. The clinker and the required amount of gypsum are ground to a fine powder in horizontal mills similar to those used for grinding the raw materials. The material may pass straight through the mill (open-circuit grinding), or coarser material may be separated from the Read More; cutlery. In cutlery: Cutlery manufacture

Contact

Preparation Of Cement Raw Material Cement

网页The cement raw materials is formed with calcareous materials, clayey materials and slight corrective material in appropriate proportion, and grinded into certain fineness. The raw material production of cement

Contact

AIR POLUTION AND AIR POLLUTION CONTROL IN

网页2017年12月20日 Cement Industry. Cement manufacturing involves mining; crushing, and grinding of raw materials; calcination in a rotary/vertical kiln; cooling of the clinker; mixing with gypsum; and milling, storing, and bagging the finished cement. The process is very energy-intensive.

Contact

Analysis of material flow and consumption in cement production

网页2016年1月20日 In the surveyed cement plant, three balances are established between input and output material in the raw mill, clinker production, and cement grinding system. 2.48 t, 4.69 t, and 3.41 t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages; waste gases

Contact